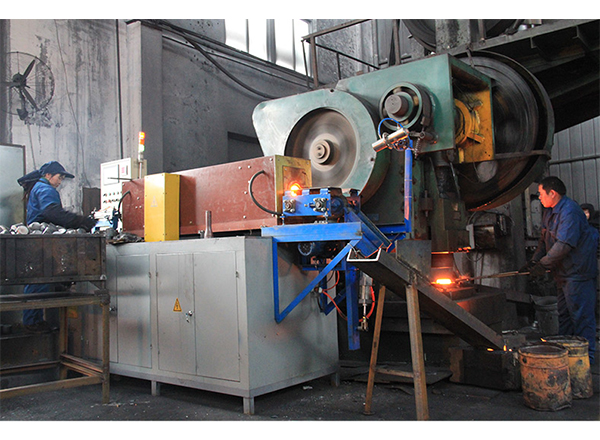

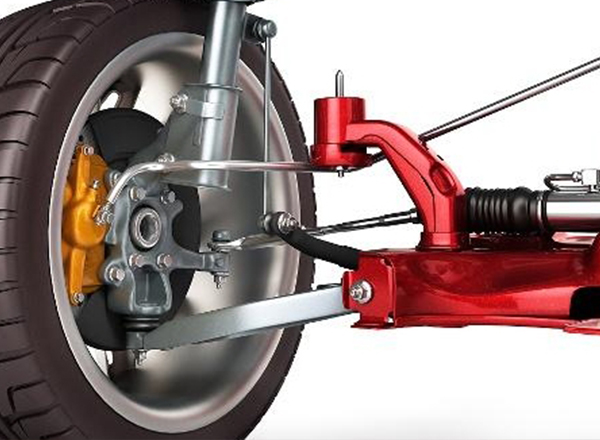

The compact bar stock heat treatment equipment is a smart, integrated system specifically designed for small to medium-sized batches and multiple specifications of bar stock heat treatment. It addresses the pain points of traditional large-scale heat treatment lines, such as large space requirements, high costs, and slow changeover times. It is suitable for the flexible production needs of precision parts processing companies, laboratories, and small and medium-sized manufacturing workshops, enabling integrated quenching and tempering heat treatment of bar stock.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200