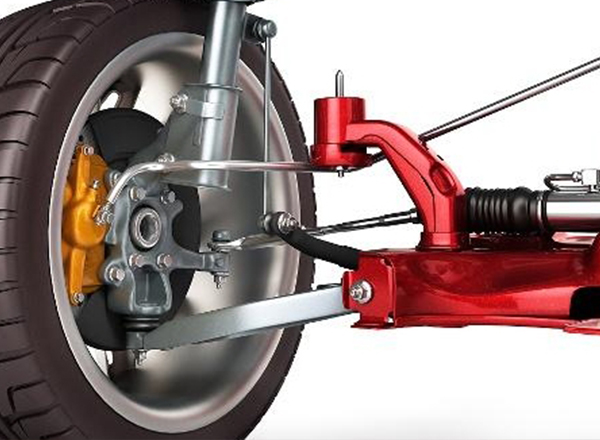

Steering knuckles withstand enormous friction during operation, thus requiring high hardness, high wear resistance, and a long service life. We typically use a medium-frequency induction heating machine for quenching heat treatment. However, due to various factors, steering knuckles can develop quenching cracks. Steering knuckle failure not only causes vehicle malfunctions but also increases the risk of serious safety accidents. Therefore, its quality is paramount. Today, the technicians at Zhengzhou Gou's will analyze the quenching crack defects and how to improve the process.

The steering knuckle workpiece is typically made of 40Cr steel or 40MnB steel. Technical requirements include a surface hardness of 52-63 HRC after quenching, a hardness of 241-285 HBW in the unhardened area, and a hardening depth of 3-6 mm for the journal, fillet, and end face, exhibiting excellent quality. We usually use a medium-frequency induction heating machine for quenching heat treatment. However, in production, we have found that some workpieces, after medium-frequency induction heating quenching, develop circumferential cracks in the fillet area, with a depth of approximately 1.2 mm, accounting for about 98.3% of the cracks. A few cracks also appear at the openings of blind holes, which are radial cracks. Cracked parts account for approximately 1.28% of the scrap.

The steering knuckle tempering process involves quenching at 860℃ for 50 minutes, cooling in a 0.2% (mass fraction) polyvinyl alcohol aqueous solution, followed by tempering at 600℃ for 3 hours. The medium-frequency induction heating machine has a power of 100kW and a frequency of 8000Hz. The location and depth of the crack in the steering knuckle indicate that the crack on the workpiece surface is caused by the superposition of structural stress and thermal stress in the workpiece after medium-frequency induction heating quenching, which leads to tensile stress concentration and the tensile stress exceeding the tensile strength of the material.

(1) The tensile stress generated during medium-frequency induction heating quenching is the result of the combined effects of structural stress and thermal stress. Its peak value is near the inner and outer sides of the hardened layer or in the transition layer region. The magnitude of the tensile stress is closely related to the temperature gradient during heating; the greater the temperature gradient and the narrower the transition layer, the higher the peak value of the tensile stress. Another influencing factor is the change in the cross-sectional area of the workpiece. Stress concentration occurs at the point of cross-sectional area change during quenching, which easily leads to cracks and workpiece fracture. The third influencing factor is the depth of the hardened layer. As the depth of the hardened layer increases, the peak value of the maximum tensile stress shifts to the center of the workpiece, and the peak value decreases, and vice versa. The depth of the hardened layer is an important cause of quenching cracks. The fourth influencing factor is the hardened transition zone, which is often where the peak value of tensile stress is located. Quenching defects and cracks often occur in the transition zone, and it is also a region prone to fatigue cracks.

(2) Overheating at blind holes: Half of the inner side of the blind hole is within the hardened zone. Due to its structural characteristics, the temperature at the blind hole is often higher or overheated, resulting in high quenching stress in the workpiece and a decrease in the strength of the overheated zone, making it prone to quenching cracks. (3) Insufficient heating at the fillet area results in a shallow hardened layer at the steering knuckle fillet; the peak tensile stress is near the fillet, making it prone to cracking after medium-frequency induction heating quenching.

Through continuous analysis, we propose the following process improvement measures:

(1) Improve the inductor design, making the small bottom diameter of the effective coil's inner conical surface 66mm, and the gap between the inductor and the workpiece 4-4.5mm, to ensure a suitable quenching temperature without overheating the blind hole, and achieving a hardened layer depth of 3-6mm.

(2) Increase the chamfer of the blind hole, and after quenching heating, air cool for 1.0-1.2s to lower the temperature of the blind hole and reduce quenching stress.

(3) Optimize the quality of pre-heat treatment. After tempering, a uniform tempered sorbite structure should be obtained, which helps reduce quenching stress and the tendency for quenching cracks.

(4) After medium-frequency induction quenching, induction self-tempering should be performed immediately. After the workpiece stops water cooling, the residual heat of the workpiece rises to 220-250℃, causing the hardened layer structure to self-temper. The temperature is slightly higher but the time is short. After treatment, the workpiece surface has good hardness and wear resistance, the structure is stable, and the peak tensile stress decreases, eliminating the risk of workpiece cracking.

(5) Using a half-circle induction heater allows for simultaneous overall induction quenching of the workpiece's hardened zone, replacing continuous induction quenching. The advantage is that the overall induction heating speed is slow, and the heating time is four times that of the latter. Therefore, the workpiece gradient is small, the width of the transition layer after quenching increases, the peak tensile stress shifts to the center of the workpiece, and the peak tensile stress decreases, which is very beneficial for reducing workpiece cracking.

Workpieces always develop various defects during heat treatment. Therefore, mastering defect prevention measures and workpiece improvement measures is extremely important. Zhengzhou Gou's has been engaged in the production and sales of medium-frequency induction heating machines for twenty years and has a thorough understanding of workpiece heat treatment. For more information on workpiece heat treatment, please feel free to contact us.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200