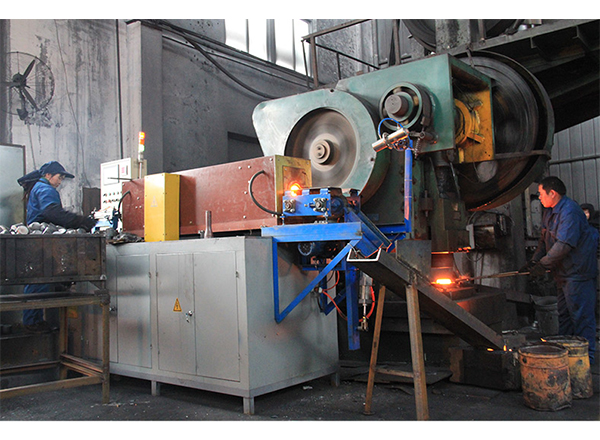

The screw is a screw similar to a bolt, which is often used in decoration. In the application, the screw needs to withstand a certain tensile strength and friction, and the quenching process of the screw will increase its two properties. Now we have eliminated the old-fashioned heating method and use the screw quenching production line for quenching and tempering. The screw quenching production line mainly consists of ultrasonic quenching equipment, touch operating table, cooling system, incoming and outgoing material storage racks, etc. The screw quenching production line adopts advanced scientific CNC operating system and reliable equipment parts. During the heating process, the heating speed is fast and the workpiece will not be oxidized or deformed. Automatic integrated design, automatic loading and unloading. The infrared thermometer automatically detects online, and the temperature, time and power can be adjusted freely. During quenching, the diameter and length of the tooth bar are adjustable, and the quenching range is large. The CNC console provides centralized control, either manually or automatically.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200