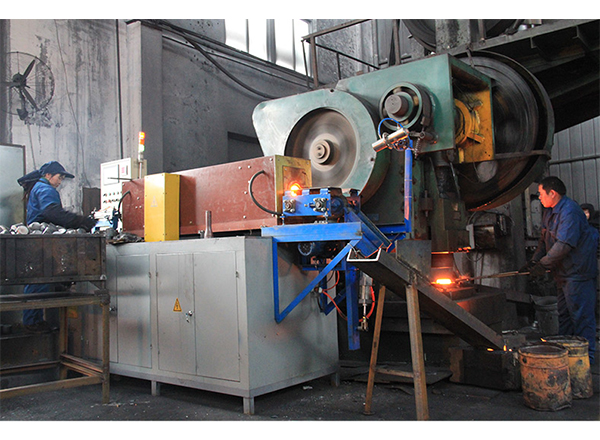

The flat steel annealing production line equipment adopts high-quality imported power devices MOSFET tubes, IGBT solid-state power modules and our company's third-generation frequency conversion technology. And it has an independent cooling system to ensure that the machine can work continuously for 24 hours at maximum power, improving the performance and quality of the equipment. It has timing function, heating time, holding time, digital setting, heating current and holding current that can be adjusted individually. It has constant current and constant power control functions to improve heating efficiency, fast heating speed, uniform heating on the workpiece surface, and energy consumption is only 20-50% of the high frequency of electronic tubes, achieving energy saving effects. Equipment fault self-diagnosis, overcurrent, overvoltage, overheating, water shortage, lack of water and other multiple protection and display. It has the characteristics of gas protection device, fast annealing, and the pipe will not deform after annealing.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200