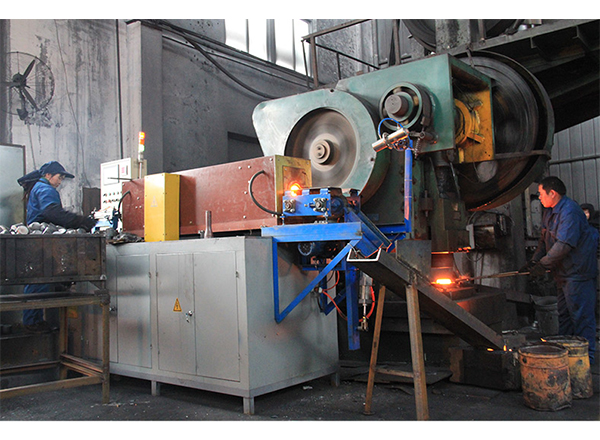

The hot-rolled plate medium-frequency annealing production line produced by Zhengzhou Gou's is fully automatic and intelligently controlled. The main control console computer monitors the entire production line process. If any problems occur, they can be displayed on the screen, which is efficient and energy-saving. The entire production line consists of a main control console, medium frequency annealing equipment (power supply), automatic loading and unloading racks, infrared thermometers, etc. It has simple and convenient operation, high reliability, strong anti-interference ability and fast heating speed. Using imported transistor IGBT power devices, it has a long service life and stable equipment. Using series and parallel resonant circuit design, it is more energy-saving, has higher power factor and lower harmonic interference to the power grid. High-quality large capacitor, high temperature resistance, full load, continuous operation for 24 hours.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200