Definition of rolling:

The process of plastic deformation of metal by compression between two rotating rollers. Metals can be rolled to obtain certain shapes, sizes and properties.

Types and uses of rolled steel:

Depending on the different shape characteristics of steel, steel can be divided into steel sections, wire rods, steel plates, strip steel, steel pipes and special steel, etc.

Basic components of a rolling mill:

The equipment for rolling steel is called a rolling mill. A rolling mill consists of rollers, a working frame, a gear frame, a connecting shaft and coupling, a main motor, etc.

Classification of rolling mills:

(1) Classification by the purpose of the rolling mill

① Primary rolling mill: named after the diameter of the roll, for example: 1150 primary rolling mill;

② Section steel rolling mill: named after the roll diameter or the pitch diameter of the herringbone gear in the gear stand, for example: 800 rolling mill;

③ Plate and strip steel rolling mill: named after the roll body length, for example: 1700 plate and strip steel rolling mill;

④ Steel pipe rolling mill: named after the maximum outer diameter of the steel pipe that can be rolled, for example: 140 pipe rolling mill;

⑤ Special rolling mill: rolling wheels, wheel hoops, steel balls, gears, bearing rings, etc.

(2) Classification by roller assembly form:

① Horizontal mill: a mill with horizontally placed rollers, such as two-roller mill, three-roller mill, four-roller mill, sixteen-roller mill, etc.;

② Vertical mill: a mill with vertically placed rollers;

③ Universal mill: a mill with both horizontal and vertical rollers arranged in the working machine frame;

④ Inclined roller mill: a mill with inclined rollers.

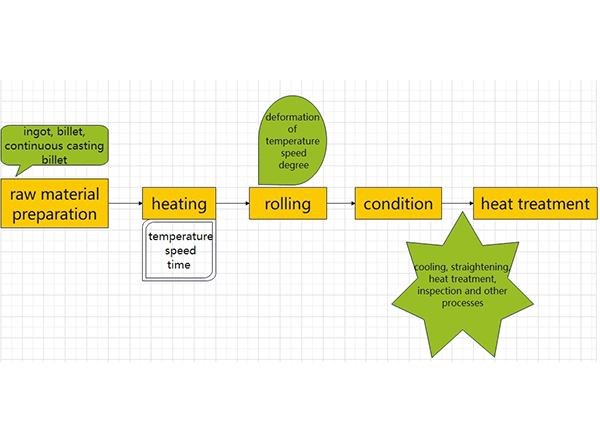

Steel rolling process:

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200