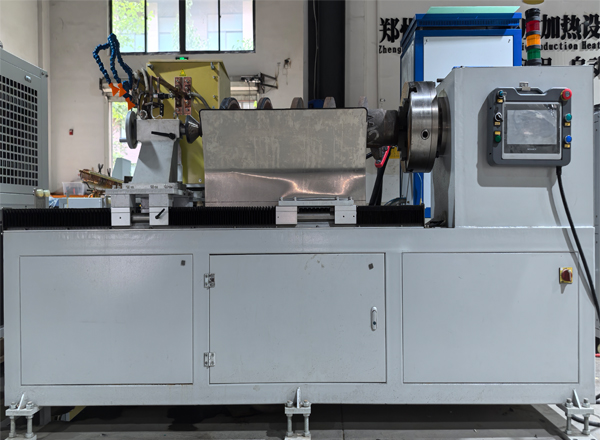

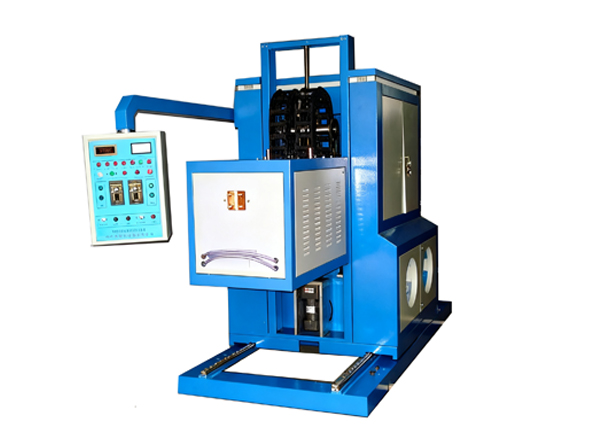

The equipment employs a CNC system or PLC and frequency conversion speed control system to achieve workpiece positioning and scanning. It connects to an inductive power supply via PLC for fully automated production. It features energy saving, environmental protection, intelligence, automation, low oxidation, and low deformation. It boasts high control precision and automation, resulting in consistent workpiece quality and a uniform hardened layer after heat treatment. No manual adjustment is required during quenching. The equipment automatically completes the quenching process, achieving high heating efficiency and low labor intensity. It offers continuous quenching, simultaneous quenching, segmented continuous quenching, and segmented simultaneous quenching functions. Utilizing a workpiece movement method, it can achieve continuous scanning quenching, segmented scanning quenching, and segmented overall quenching of parts. The quenching speed and operating rotation speed are infinitely adjustable.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200