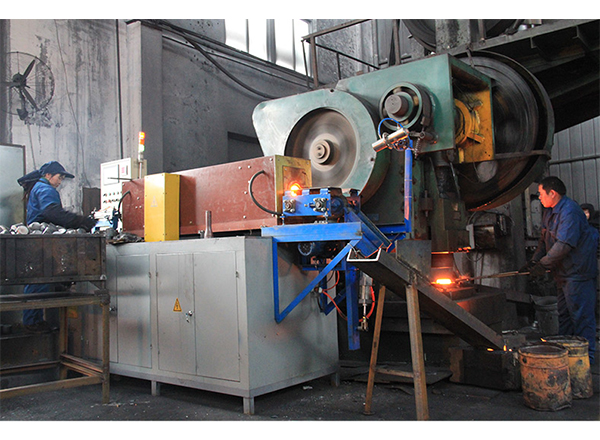

The brass forging induction heating production line is a specialized automated heating equipment designed for the hot forging process of brass wire (such as upsetting, drawing, and bending). Its core technology relies on electromagnetic induction eddy current heating, combined with the physical properties of brass (good conductivity and low melting point) to achieve efficient and precise heating. The high compatibility of induction heating technology with the brass forging process gives it significant advantages over traditional heating methods (such as coal furnaces, resistance furnaces, and gas furnaces), mainly in terms of production efficiency, cost control, and product quality.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200