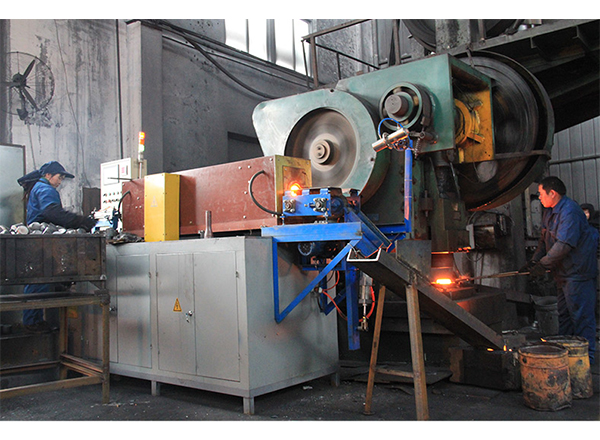

Gear racks need to withstand a certain tensile strength and friction, and the induction hardening process increases both of these properties. We have now replaced the old heating methods with an induction hardening production line for gear racks. The gear rack induction hardening production line mainly consists of hardening equipment, a touch control panel, a cooling system, and loading and unloading racks. The gear rack induction hardening production line utilizes an advanced scientific CNC operating system and reliable equipment components. During the heating process, the heating speed is fast, and the workpiece does not oxidize or deform. The integrated automatic design allows for automatic loading and unloading. An infrared thermometer provides automatic online detection, and temperature, time, and power can be freely adjusted. During hardening, the diameter and length of the gear rack are adjustable, allowing for a wide range of hardening applications. The CNC control panel provides centralized control, allowing for both manual and automatic operation.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200