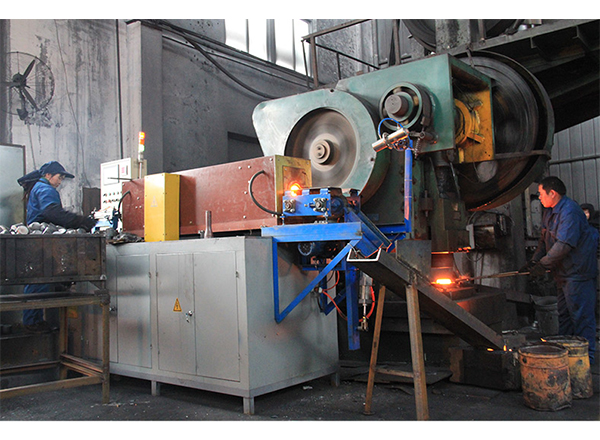

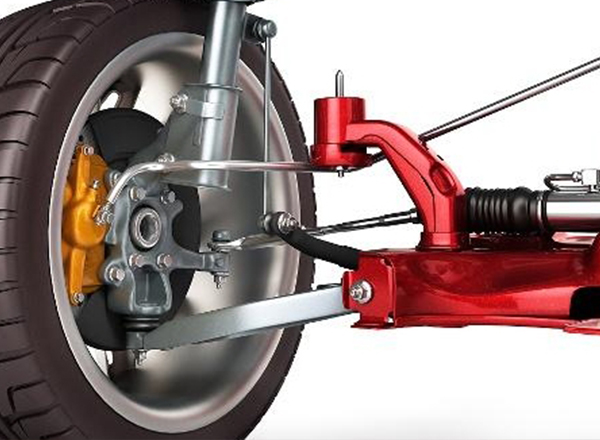

As a core transmission component in automobiles, wind power, rail transit, and construction machinery, the surface wear resistance, fatigue strength, and dimensional stability of the drive shaft directly determine the reliability and service life of the entire machine. This automatic induction hardening production line for drive shafts, relying on advanced induction heating technology and an intelligent control system, is specifically designed for the surface strengthening process of shaft-type parts. It achieves fully automated operation from feeding, positioning, hardening, and cooling to inspection and unloading, addressing the industry pain points of traditional hardening processes such as excessive manual intervention, large parameter fluctuations, high deformation rates, and high energy consumption. It provides an integrated solution for the mass production of high-quality drive shafts.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200