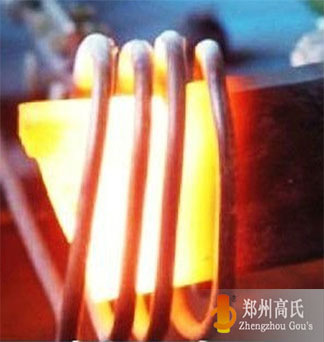

For turning tool welding with a specification of 30*30mm, we recommend using 30kw medium frequency induction heating equipment. The intermediate frequency induction heating equipment produced by Zhengzhou Gou's can not only weld the workpiece, but also perform diathermy, annealing, quenching, melting, etc., and is widely used.

Performance characteristics of 30kw medium frequency induction heating equipment - turning tool welding equipment

1. The self-control type can adjust the heating time, heating power, holding time, holding power and cooling time; it greatly improves the quality of heating products and the repeatability of heating, and simplifies the operation technology of workers.

2. Adopt the well-known company Unipack IGBT power device and unique inverter technology, 99% load duration design, 24-hour operation under the maximum power, high reliability guarantee.

3. Especially safe, the output voltage is lower than 36V, avoiding the risk of high voltage electric shock.

4. It occupies a small area and is easy to operate, which can be learned in a few minutes.

5. It is light in weight, small in size, and easy to install. It only needs to be connected to a 380V three-phase power supply, water in and out, and it can be completed in a few minutes.

6. The sensor can be disassembled and replaced freely and quickly, which greatly reduces the oxidation deformation of the workpiece compared with rapid heating.

7. The equipment has the control function of constant current and constant power, which greatly optimizes the heating process of metals, realizes efficient and rapid heating, and gives full play to the superior performance of the product.

8. It is a newer environmental protection product that replaces the heating of oxygen, acetylene, coal and other dangerous materials. It is safer and more secure to produce without open flames.

9. The equipment has complete automatic protection functions such as overcurrent, overvoltage, overtemperature, water shortage, and lack of water, and is equipped with a fault self-diagnosis and alarm system.

10. The heating efficiency is as high as 90%, the energy consumption is only 20%-30% of the high frequency of the old-fashioned electronic tube, almost no electricity is used in the standby state, and it can work continuously for 24 hours.

Advantages of 30kw medium frequency induction heating equipment-turning tool welding equipment

1. Small size, light weight, simple installation and convenient operation.

2. Safe and reliable, no 10,000 volts of high voltage, very safe for operators.

3. High efficiency and obvious power saving, 60% power saving compared with traditional high-frequency equipment, 20% power saving compared with thyristor intermediate frequency.

4. The unique cooling circulation system ensures that the equipment can work continuously for 24 hours.

5. The frequency band is wide, which can meet the pre-forging heating, heat treatment, brazing, etc. of different workpieces.

Medium frequency induction heating equipment has complete functions and small size, so it can be used not only in factories, but also in laboratories. In general, you can use our equipment regardless of the size of the space.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200