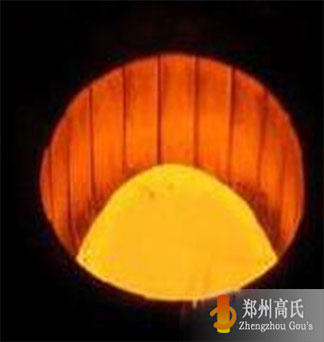

The application of intermediate frequency smelting in metal is not only suitable for laboratories but also for large-scale steel and aluminum alloy industries. It also has a good effect on small-scale gold and silver smelting, especially for the processing of gold and silver jewelry. In the processing of gold and silver jewelry, the output is generally not large in the smelting stage, but the required purity is higher. Our medium frequency induction heating furnace can be equipped with electromagnetic stirring device, which will greatly improve the smelting purity of metals.

Medium frequency induction heating furnace, small size, light weight, small footprint, simple and convenient installation, integrated design of cooling water system and host, the weight of the transformer is only about 20kg, it can be connected to the crucible, and can also be connected to the automatic dumping furnace , with a higher degree of automation, which can simplify manual operations to the greatest extent and facilitate installation on the production line.

While we recommend and select a suitable medium frequency induction heating furnace for you, we will also select a suitable crucible and pouring furnace for you. The design and manufacture of the inductor are also very important. The shape, number of turns and spacing of the inductor will affect The melting effect of the metal. Therefore, a well-made sensor is another important beacon for your safety. In-depth understanding of possible accidents during the use of crucibles and dumping furnaces, and timely response can not only save your time, but also ensure that the equipment is safe and sound, and reduce the risk of damage to the intermediate frequency induction heating furnace. Details about this , you can refer to the content of other sections of our website.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200