1. Let’s first talk about the working principle of the stepping mechanism.

The push-type induction heating furnace has only a pair of water-cooled guide rails in the inductor. The blanks are placed on the guide rails, and the blanks are pushed one by one from one end of the inductor using hydraulic, pneumatic or mechanical means to achieve the required results through the inductor. Heat up the temperature and push out the other end of the sensor. The stepping induction heating furnace has two pairs of water-cooled guide rails in the inductor. One pair of guide rails is fixed and is used to bear the mass of the blank during heating; the other pair of guide rails is movable and is used to lift the blank to the direction. Feed the length of one material level forward.

2. Advantages and disadvantages of stepping induction heating furnace

The push-type medium frequency induction heating furnace has a relatively simple blank feeding mechanism and is easy to manufacture and maintain. The gap between the coil of the inductor and the blank is small. There is only a pair of water-cooled guide rails in the inductor, so the heating efficiency is high. However, due to The blanks are pushed forward one by one. When the diameter of the blanks is larger and the heating temperature is higher, bonding between the blanks is easy to occur. At the same time, since the blank is pushed forward, the friction between the blank and the guide rail affects the service life of the guide rail. Another disadvantage is that when the furnace is shut down, the blanks remain in the inductor and cannot be fully pushed out. Therefore, this push-type induction heating furnace is suitable for heating blanks whose diameter is less than 60mm and the heating temperature is lower than 1200°C. The stepping induction heating furnace has two pairs of water-cooled guide rails, and a pair of movable guide rails hold up the blank for horizontal movement. This increases the gap between the inductor coil and the blank, increases magnetic flux leakage, and reduces the heating of the inductor. Efficiency, the power consumption increases by 5%-10% compared with push-type induction heating furnace. Since the blank is held up by the movable guide rail for horizontal movement, there is no friction between the blank and the guide rail, and there is no problem of extrusion between the blanks. Although the heating temperature is high, there will be no bonding phenomenon. When the furnace needs to be shut down, all the blanks in the inductor can be removed. Therefore, the stepping induction heating furnace is suitable for heating blanks with a diameter greater than 80mm and a heating temperature greater than 1200°C.

3. Structure of stepping induction heating furnace

The stepping induction heating furnace for heating large steel rods is mainly composed of an inductor, a stepping mechanism, a thermal insulation cover and a equalizing chamber.

Inductor: Use 16mm x 16mm x3mm pure copper tube to wind into three larger inner diameter coils. The copper pipe is covered with an insulating layer and is cooled by water during operation. There is a heat-resistant sleeve in each coil, and aluminum silicate fiber felt is filled between the two for heat insulation. Insulated end plates and tie rod bolts are used to form a whole. Each sensor is equipped with 4 steel rods. Press Imin to feed one piece of material. Steel The total heating time of the rod is 12 minutes. There is a space the length of two steel rods between the two inductors. A stepping mechanism is installed to support the movable guide rail and allow the steel rods to have a soaking time of 4 minutes. The long distance between the sensors is beneficial to heating and temperature uniformity, but it brings difficulties to the design and layout of the stepper mechanism. The movable guide rails are prone to bending because they carry many steel rods, hindering the feeding of materials. The first inductor has fewer turns and higher power, and quickly heats the steel rod to about 900°C; the second and third inductors have more turns and lower power, and continues to heat the steel rod to 115°C. This sequential induction heating heats up quickly and has high efficiency, which is beneficial to reducing the radial temperature difference of the blank.

Stepping mechanism: Two pairs of fixed and movable guide rails are made of heat-resistant stainless steel tubes, and are cooled by water during operation. The support frame is welded with section steel. The stepping mechanism adopts hydraulic transmission. One hydraulic cylinder makes the movable guide rail rise and fall, and the other hydraulic cylinder makes the stepping mechanism move forward by one material distance, which is controlled by interlocking of the stroke limit switch. By adjusting the switch position, blanks within a certain length range can be sent . The feeding cycle time is controlled by the time relay, and changing its setting value can adjust the blank heating temperature and productivity. A blank is fed 16 times step by step, and completes the heating through all the sensors. Furnace frame: made of welded steel, The sensor, stepping mechanism and operation control device are installed on it to form a whole. Insulation cover and equalization chamber: Set up an insulation cover between the two sensors to reduce the heat loss of the blank during the heating process. In the third induction The discharge end of the machine is equipped with a homogenization chamber to reduce the radial temperature difference of the blank. Both are made of steel plates and lined with aluminum silicate fibers inside.毡。

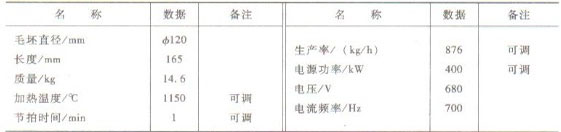

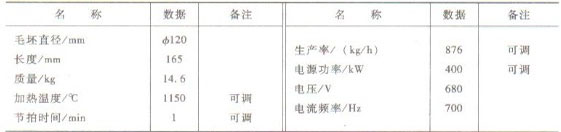

4. Main parameters of heating furnace

The main technical parameters of the large steel rod stepping medium frequency induction heating furnace are shown in the table below.

5. Temperature measurement test

In order to understand the operating performance of the heating furnace, temperature measurement tests were conducted on the temperature changes of the blank during the heating process and the radial temperature uniformity at the end of heating, as well as the influence of the water-cooled guide rails on the temperature uniformity of the blank. Drill three small holes in the same representative section in the middle of the blank, and rivet three 6mm nickel-chromium-nickel-aluminum armored thermocouple heads into the small holes. Use the compensation wire to connect to the XWX-2042 automatic temperature recorder for measurement. In order to facilitate the thermocouple and compensation wire to pass through the sensor smoothly with the blank, the movable guide rail was removed, and the blank was placed on the fixed guide rail and pushed and heated by a hydraulic cylinder. The temperature difference between the surface and the core is 40-94℃, and the temperature difference between the circumferential surface is 54℃. This is caused by factors such as the blank contacting the water-cooling guide rail, short heating and equalizing time, and high power frequency. When the movable guide rail is put into operation during normal production, the radial temperature difference will also increase, and local over-temperature or under-temperature may occur. During subsequent transportation and thermoplastic processing, although there is a certain temperature equalization effect, it has little effect on improving the circumferential temperature difference of the blank. Therefore, when used in stamping operations, a horseshoe shape will appear at the mouth of the product, and the wall thickness will be uneven. If the process requirements cannot be met, corresponding measures must be taken to reduce the temperature difference of the blank. Therefore, an equalization chamber is added at the discharge end of the third inductor to reduce the temperature difference on the circumference of the blank.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200