During the heating and forging process of the crankshaft mold using a medium frequency induction heating power supply, there are many factors that affect its service life, such as the type and state of the forging equipment, the material and shape of the crankshaft, etc. So how to specifically improve the service life of the crankshaft mold is as follows The editor will take you to find out:

Improving the life of the mold is a systematic project. Only by doing all the work well can the life of the mold be improved. However, each type of forging has key factors for improving the life of the mold. The key factors for the crankshaft, that is, the main measures to improve the life of the crankshaft mold are:

(1) When designing the mold, the thickness of the skin between the crankshaft balance blocks must be appropriate. The design can be optimized based on experience or computer numerical simulation. An excessively thick skin will increase the wear of the flange during forging.

(2) Use medium-frequency induction heating power to heat-treat the mold to improve the hardness of the mold: it can enhance the wear resistance and help improve the life of the crankshaft forging die. However, if the hardness exceeds a certain value, it will accelerate the formation of cracks in the forging die and even occur. Embrittlement is detrimental to the life of the forging die, so the surface of the crankshaft forging die should be strengthened.

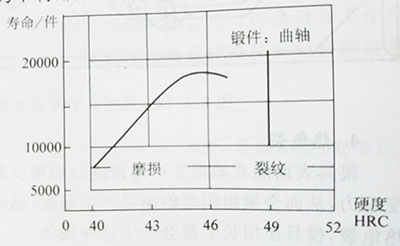

The figure below shows the relationship between the average life of the forging die and the surface hardness of the die bore when two factories in Germany forged the same crankshaft forgings on mechanical presses. Generally speaking, the mold hardness is suitable between HRC43 and HRC48.

The hardness of mechanical press molds can be higher, with a smaller value for large molds and a larger value for small molds. However, Germany has used the complexity of forgings as a basis for selecting mold hardness since the early 1960s.

(3) During production, the medium-frequency induction heating power supply should preheat the mold thoroughly and evenly, lubricate and cool it in time, and ensure that its working temperature is lower than the tempering temperature of the mold material.

(4) For crankshafts with deep balance block die chambers, the heat treatment fracture toughness of the forging die must be improved to prevent brittle fracture of the flange between the balance block die chambers.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200