The principle of sorbitization of high carbon steel wire can be roughly divided into two processes: austenitization process and isothermal quenching. The organizational structural changes that occur during these two processes are described below.

1. Austenitization process of steel

When high carbon steel wire is sorbitized using a medium frequency induction heating machine, the steel wire is first heated to the single-phase austenite zone for austenitization. The purpose of austenitization is to obtain austenite with uniform carbon content and a crystal structure with fine grains. Create good conditions for isothermal decomposition of supercooled austenite. The austenitizing temperature changes with the carbon content. For high carbon steel with a carbon content of 0.60% to 0.95%, the austenitizing temperature is 880 to 950°C. After austenitization is completed, austempering is performed immediately.

2. Isothermal decomposition process of supercooled austenite

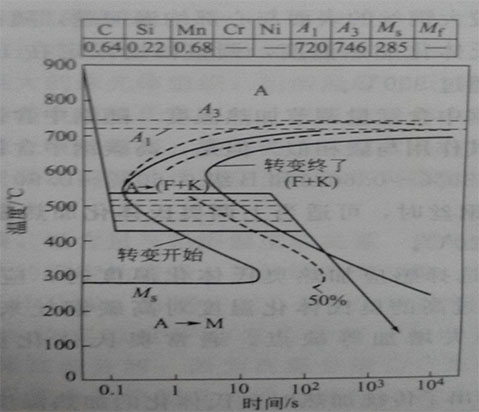

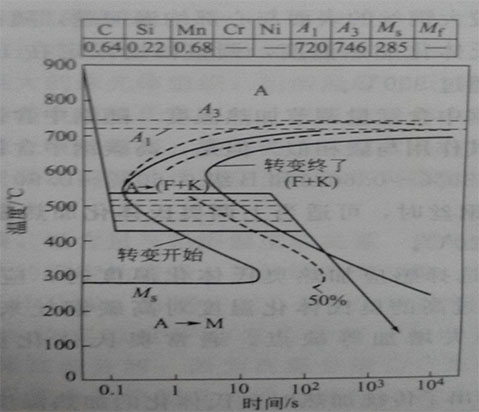

Isothermal decomposition is the process of transforming austenite into pearlite within a certain temperature range, that is, A→P(F+K). The figure below shows the theoretical cooling curve of lead bath quenching for high carbon steel wire with a carbon content of 0.64%. It can be seen from the figure that the lead bath quenching process is the isothermal decomposition process of supercooled austenite. The rhombus area in the figure represents the A→P transformation area. From the curves of the start and end of transformation, it can be seen that the transformation of supercooled austenite into pearlite is faster and generally ends within 10 seconds. This provides a theoretical basis for the length of holding time in the lead bath. It can be seen from the transformation starting temperature that the optimal transformation temperature is 450~550°C, which provides a theoretical basis for controlling the lead bath temperature.

3. Microstructure of high carbon steel wire sorbitized products

In summary, the product of supercooled austenite lead bath isothermal quenching is pearlite. However, in fact, as the transformation temperature of supercooled austenite decreases and the cooling rate increases, the lamellar spacing of the transformation product pearlite continues to decrease. At this time, according to the pearlite lamellar spacing of the transformation product, the transformation product can be subdivided into the following three organizational structures: coarse pearlite (150-450nm), fine sorbite (80--150nm) and finer Troostite (30~80nm). Therefore, the product obtained by sorbitization treatment of high carbon steel wire is composed of these three organizational structures. It is hoped that the proportion of the latter two organizational structures is as high as possible.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200