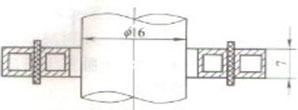

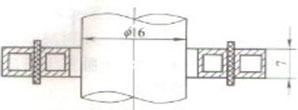

Today we talk about several different sensors in the medium frequency induction heating equipment. When heating a section of a cylindrical surface of a small cylinder, for example, a section of a cylinder of 6mm If the disc-shaped double-turn inductor is used instead as shown in Figure 7-38, the efficiency of the inductor will immediately increase due to the increase in the effective coil impedance, and the heating time can often be shortened to less than 1s, and its effect is similar to that of a current collector.

The first type, branch return type sensor.

This kind of inductor, as shown in Figure 7-39, can heat the end faces of multiple cylindrical workpieces, such as rows of small cylindrical ends, valve ends, etc.

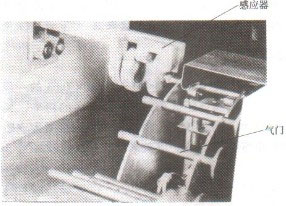

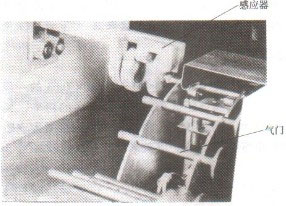

Second type, solenoid coil heating valve end sensor.

The solenoid coil heating valve tip sensor is shown in the figure. The center of both ends of the solenoid coil is the area where magnetic lines of force are concentrated. This position is used to heat the valve tip to achieve practical results.

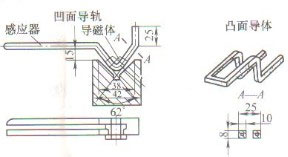

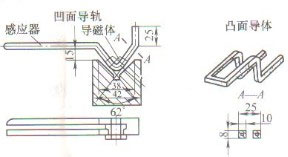

The third type, plane scanning quenching sensor such as machine tool guide rail.

The machine tool guide rail and other plane scanning quenching sensors are shown in the figure. The structure is all loop type, and the front tube machine tool guide rail and other planes scan the quenching sensor in a gap of one tube width to improve the sensor efficiency. The effective ring is inlaid with ferrite or processable magnetic conductors to improve the efficiency of the sensor. When the workpiece is placed horizontally, a compressed air nozzle can be added to one end to prevent the quenching water from flowing onto the heating surface.

The fourth type, cylinder liner inner hole heating scanning quenching sensor.

The inner hole heating sensor requires the gap between the effective ring and the inner hole of the workpiece to be as small as possible to improve efficiency. Due to the ring effect, if a rectangular tube is used as the effective ring, a magnet must be installed, as shown in the figure. In the absence of a magnetic conductor, it is also an application to use a heat-resistant resin as a cooling water channel, which allows the current to flow only to the copper conductor of the effective ring, as shown in the figure.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200