The camshaft is an important part of the engine valve system. The engine of a medium-sized truck is generally a 6-cylinder internal combustion engine. There is an intake cam and an exhaust cam corresponding to each cylinder. Therefore, there are 12 cams on a camshaft, 4 main journal, a gear and 2 eccentrics.

The camshaft is generally made of 45 steel and uses induction quenching. Its surface hardness requirement is HRC55-63 and the depth of the hardened layer is 2-5mm. Mass-produced camshafts mostly use an 8KHZ medium-frequency induction quenching machine for medium-frequency quenching. Single-piece or small-volume camshafts also use 250KHZ high-frequency quenching. If the width of each quenching part is the same, one inductor can be used for quenching. If the width of the quenching part is different, one or several inductors can be used for quenching according to the situation.

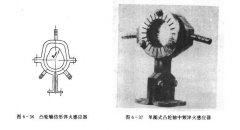

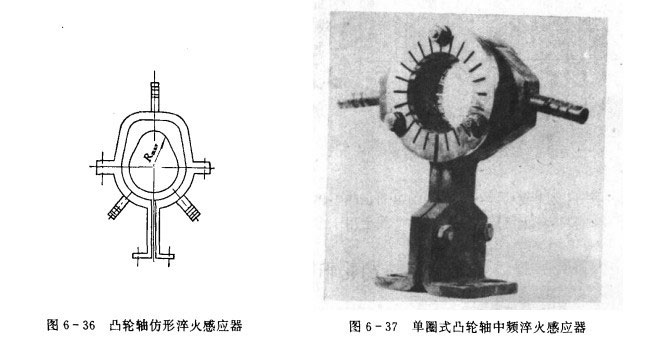

The high-frequency quenching sensor of the camshaft can be circular or profiled. Generally speaking, the cam hardened layer quenched by the profiling sensor is also profiling. The profiling sensor alone is difficult to manufacture and troublesome to operate. The effective circle of the sensor is split and consists of two parts. As shown in Figure 6-36.

The effective circle of the medium frequency quenching inductor is circular and divided into single-turn inductor and double-turn inductor. The single-turn inductor has one effective circle, and the double-turn inductor has two effective circles. , the latter is produced by quenching two camshaft wheels at the same time.

The camshaft has several cams on one shaft. The main journal, gear and eccentric wheel need to be induction hardened. The distance between them is generally small. The minimum distance between the cam and the main wheel is 9.7mm, so the camshaft The medium frequency quenching inductor must have a shielding device. When a cam or a main journal is inductively heated, the cams or main journals on both sides of it can be protected so that the escaping magnetic lines cannot inductively heat their edges. Otherwise, if they Already quenched, it will be softened by induction tempering. There are three types of magnetic field shielding devices on intermediate frequency sensors: copper ring shielding method, low carbon copper ring shielding method, silicon steel sheet shielding method, etc.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200