1. Name of medium frequency induction heating surface quenching workpiece

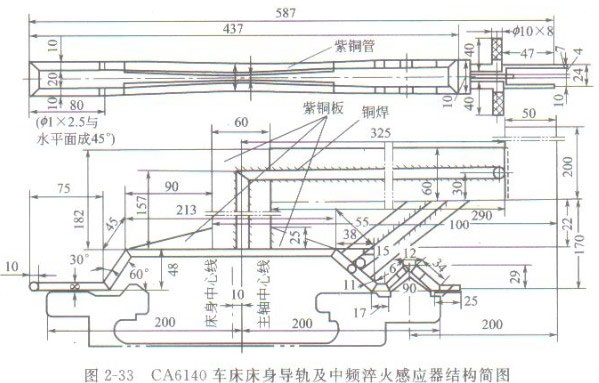

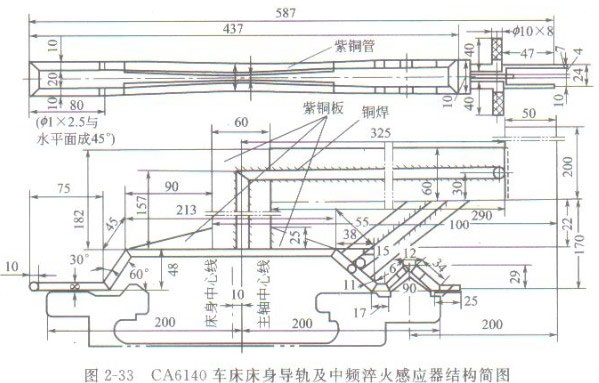

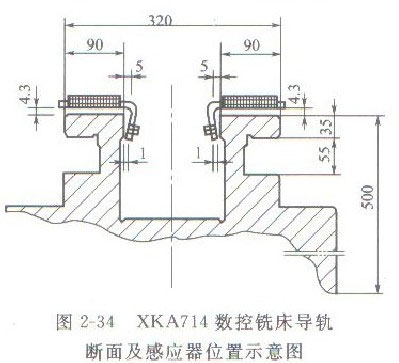

The structure diagram of the medium frequency quenching sensor of the lathe bed guide rail is shown in Figure 2-33, and the material used is HT300.

2. Medium frequency induction heating surface quenching heat treatment technical conditions

Intermediate frequency quenching electrical parameters: primary voltage, 750V. Primary current, 70A. Primary side coil turns, 12 turns. Secondary side coil turns, 1 turn. Quenching power, 60~70kW. Power factor, 0.90.

3. Process specification for medium frequency induction heating surface quenching heat treatment

a. The gap between the sensor and the guide rail surface is 1.5~2mm.

b.Quenching temperature 900℃.

c. Quenching media: water

d. Cooling method: continuous injection.

4. Analysis of medium frequency induction heating surface quenching heat treatment process

a. Hardness: After medium frequency quenching, the hardness reaches 45~55HRC.

b. The depth of the hardened layer is 2~4mm.

c. Microstructure, the hardened layer is cryptocrystal, fine acicular martensite, graphite and a small amount of phosphorus eutectic, without obvious transition layer.

d. Bending deformation, center concave ≤ 0.5mm.

5. Key points for implementation of medium frequency induction heating surface quenching heat treatment technology

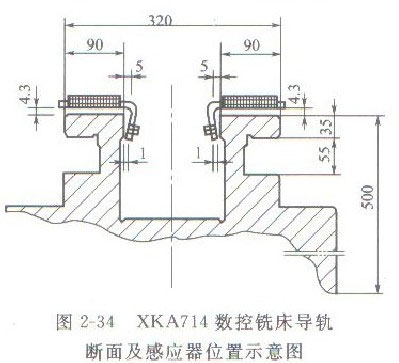

a.The yamagata heating section and flat heating section of medium frequency induction heating surface quenching inductor place the magnetizer, To increase heating efficiency and improve heating conditions. Its structure is basically the same as the high-frequency induction heating surface quenching inductor, as shown in Figure 2-34.

b. Medium frequency induction heating surface quenching process parameters should be determined according to power, maximum primary voltage and heating temperature. In the case of primary voltage ≤ 800V, select the number of primary coil turns so as to obtain the maximum output power.

c. The heating movement speed depends on the heating temperature, output power and the gap size between the sensor and the guide rail. As the power increases, the heating speed increases and the moving speed should also increase. As the gap increases, the temperature rise slows down, so the moving speed needs to be reduced accordingly.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200