There are always defects in traditional equipment for heat treatment of prestressed steel. Therefore, more and more manufacturers are now using medium frequency induction heating equipment for heat treatment. It is said that using this equipment for heat treatment can improve the stress resistance of steel. Relaxation performance, so is this the case?

Low relaxation prestressed steel wire has high elastic limit and yield limit and low relaxation rate. PC steel wire with low relaxation performance is widely used in important projects such as large bridges, elevated highways, and high-speed railways. At present, this kind of low relaxation rate steel wire must be heat treated by medium frequency heating equipment. Low-relaxation grades can only be achieved with wires stabilized by induction heating. Traditional electric furnace or lead bath tempering treatment is difficult to achieve low relaxation rate standard. After induction heating stabilization treatment, the relaxation rate can reach below 0.5%.

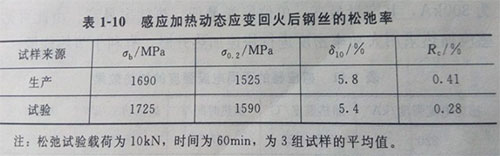

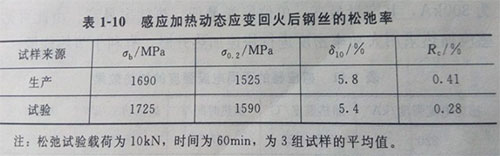

The high-carbon steel wire with a carbon mass fraction of 0.70% is subjected to dynamic strain tempering at 300-350°C by induction heating, and the relaxation rate of the steel wire with a diameter of 3.0mm is listed in the table below.

It can be seen from the above description that the heat treatment of prestressed steel by medium frequency induction heating equipment can improve its stress relaxation resistance. If you are still using traditional equipment for heat treatment, what are you waiting for, quickly change to a new medium frequency induction heating equipment.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200