|

Heating type

|

Application range

|

frequency selection

|

power selection

|

|

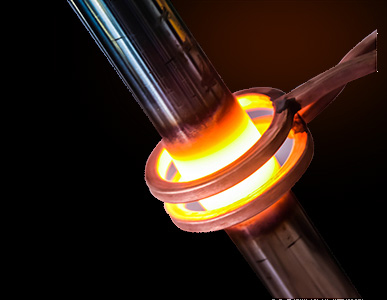

Brazing

|

Composite welding of reamers, milling cutters, drill bits, turning tools, drill bits, etc. and stainless steel pot bottoms of different materials.

|

Principle: The larger the welding volume, the lower the frequency should be. Knives with a volume smaller than 30*30*30 can use high frequency, and tools larger than 30*30*30 can use intermediate frequency. Principle: The larger the workpiece diameter, the lower the frequency should be.

|

According to the specific workpiece shape, solder, material and other conditions.

|

|

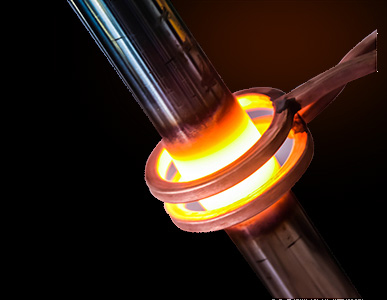

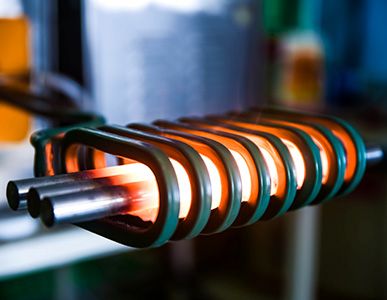

Heating

|

Hot heading and hot rolling of hardware tools, copper rods, fasteners, standard parts, auto parts, twist drills, etc.

|

Above Φ20, medium frequency (1-20KHZ)

Φ5-20, high frequency (20-100KHZ)

Below Φ5, ultrahigh frequency(100-500KHZ)

|

Choose the appropriate power according to the production efficiency, the greater the power, the faster the speed. For details, please consult the technical personnel of the company.

|

|

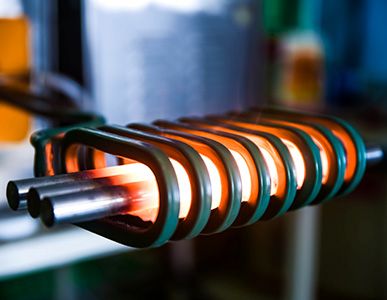

Hardening

|

Quenching of gears, sprockets, shafts, machine tool guide rail accessories, etc.

|

Principle: The shallower the workpiece requires the hardened layer, the higher the frequency should be.

Ultrahigh frequency 100-500KHZ below 1mm

1-2.5mm super audio frequency 20-100KHZ

2.5mm or more medium frequency 1-20KHZ

|

Combined with the comprehensive consideration of workpiece shape, quenching hardness, quenching method, hardened layer requirements and materials, please consult the company's technical personnel for details.

|

|

Annealing

|

Metal wire and pipe annealing, auto parts, knives and scissors, hydraulic accessories, annealing of stainless steel pots, etc.

|

Combined with comprehensive consideration of the annealing speed of the workpiece, annealing requirements and materials, please consult the technical personnel of the company for details.

|

|

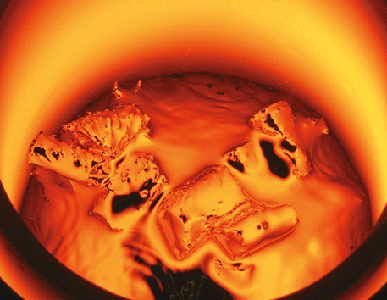

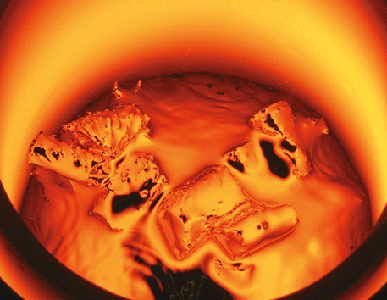

Melting

|

Copper, lead, gold, silver, and other precious metals

|

Medium frequency; small capacity optional high frequency

|

It depends on the furnace and production efficiency.

|

|

Brazing

|

Heating film for steel-plastic pipes, cables, aluminum-plastic pipes, and wires; aluminum foil sealing for beverage, food, and pharmaceutical industries.

|

on a case-by-case basis

|

It depends on the production speed, temperature and material.

|

|

Special functions and supporting equipment

|

Such as dual-frequency equipment, multi-load matching type (dual heads, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft-connected sensors.

|

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200