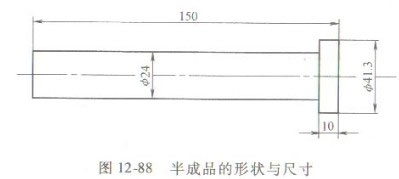

The semi-finished workpiece after processing needs to be normalized. Its shape and size are shown in the figure below. The semi-finished workpiece made of processed materials needs to be normalized. Its shape and size are shown in the figure below. The material is 20MnSi steel, the mass of each piece is 0.54kg, the required normalizing temperature is 1050°C, and the productivity is 12 pieces/min, which is 388.8kg/h.

Since the workpiece has a variable cross-section, the diameter of the small head is 24mm and the diameter of the large head is 41.3mm. The power of the selected medium-frequency induction heating equipment is 250kW and the current frequency is 2500Hz. The inductor used is a spiral cylindrical shape, the inner diameter of the induction coil is 85mm, the length is 1800mm, and it is wound with a rectangular pure copper tube of 14mm x 10mm x 2mm. The pure copper tube does not cover the insulation layer, and there is a certain gap between the turns of the coil. Use air insulation and water cooling during operation. The heat-resistant bushing in the induction coil is a quartz tube with an outer diameter of 60mm, an inner diameter of 50mm, and a length of 1800mm. An aluminum silicate fiber felt is lined between the quartz tube and the induction coil, with a thickness of 12.5mm. 12 workpieces can be placed in the induction coil. There are no water-cooled guide rails. The workpieces are directly placed in the quartz tube and pushed one after another. Every 5 seconds, a workpiece is pushed from the feed end of the sensor, and a workpiece that has been heated to 1050°C is pushed out from the discharge end of the sensor. The terminal voltage of the sensor is 1400V, the heating time of the workpiece is 1 minute, and the temperature of the workpiece is basically the same, meeting the process requirements.

The characteristics of this set of medium frequency induction heating equipment are that the terminal voltage of the induction coil is 1400V, the heat-resistant bushing is a quartz tube, and there is no water-cooled guide rail. The heating time of the workpiece is longer than theoretically calculated, which ensures that the heating temperature of the workpiece is uniform.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200