The ball screw is a key part of the transmission mechanism of a machine tool. Made of GCr15 steel, heat treated with medium frequency induction heating and quenching. The quenching machine tool is equipped with a double-track horizontal quenching machine tool for the medium frequency generator set with a power of 10OkW and 2500Hz. During medium-frequency induction heating and quenching of the screw, one end is clamped by a three-claw chuck, and the other end is held and fixed by the tailstock tip, thus limiting the elongation deformation of the workpiece during quenching and heating, causing the screw to have a bending deformation of 2-6 mm. Many of them cannot be saved by manual straightening, resulting in workpieces being scrapped, seriously affecting product quality and machine tool production, and causing large economic losses.

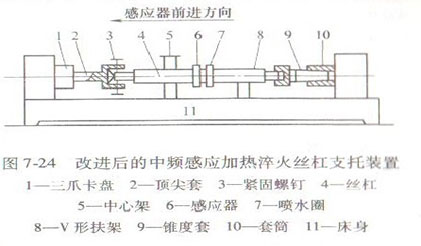

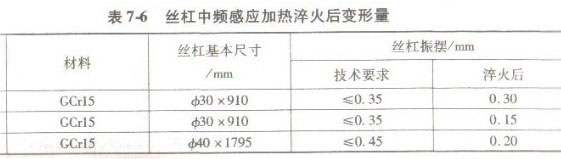

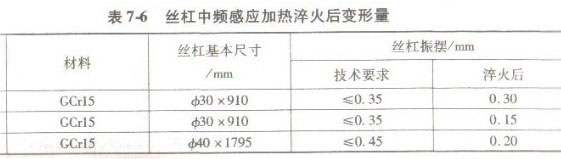

The improved medium frequency induction heating quenching screw support device is shown in Figure 7-24. The quenching device removes the tailstock tip and sleeve, and uses the tailstock tip taper hole to design a taper sleeve to reduce the swing or vibration during screw quenching. The operation and processing methods are improved to adjust the screw vibration to ≤0.15mm. When the workpiece is quenched, use a center frame and a V-shaped support frame with rollers to support the screw to prevent the screw from sagging due to heat during processing. Use a dial indicator to measure the deformation of the workpiece during processing to ensure that the deformation is within the oscillation range. Within. After medium-frequency induction heating quenching of the screw, the deformation is greatly reduced, and the deformation is 0.15-0.30mm, which meets the technical requirements. The deformation amount of the screw after medium frequency induction heating quenching is shown in Table 7-6.

After the ball screw uses an improved medium-frequency induction heating quenching process, the workpiece deforms slightly and meets the technical requirements, thus eliminating the manual alignment process, saving man-hours and costs, and improving production efficiency.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200