Flanges, also called flange flanges or flanges, are parts that are connected to each other between shafts and are used for connection between pipe ends. In order to meet the needs of the work, flanges usually require welding heat treatment. In the past, most people used traditional equipment to weld and heat-treat flanges, and there were always defects such as oxidation and deformation, which greatly affected the normal use of flanges. With the improvement of production technology, more and more manufacturers use medium-frequency induction heating machines for welding heat treatment, and the effect is very good.

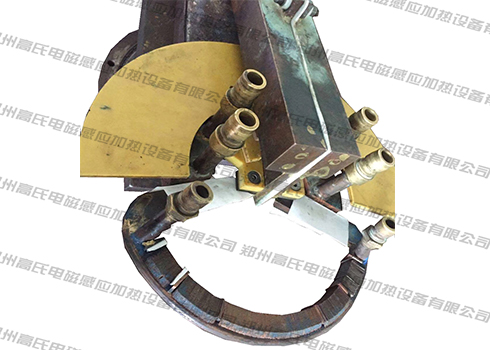

Medium-frequency induction heating machine, when it welds and heat-treats the flange, the sensor is a copy sensor made according to the flange specification. The advantage of using this kind of sensor is that it can ensure the uniformity of welding temperature and welding area, so that the welded flange has no missing welding and missing welding spots, and the appearance is quite exquisite and beautiful, basically no welding traces can be seen.

The medium frequency induction heating machine adopts IGBT inverter power device, which is highly efficient and energy-saving, and the heating is easy to control. The heating current value and heating voltage value can be set, and the current, voltage, power and frequency are all displayed. The operation is intuitive, simple and convenient. What's better is that it will not produce noise and dust, and will not produce waste smoke and waste gas when welding and heat-treating the flange, which greatly improves the working environment of workers and enables workers to realize environmentally friendly production.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl