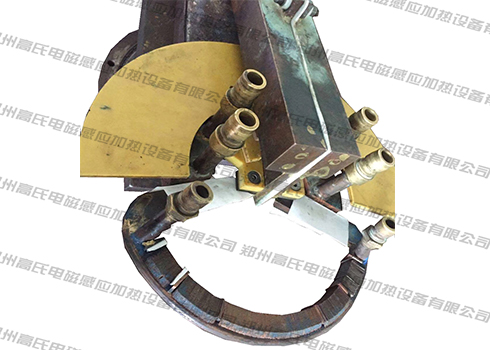

With the rapid development of mechanical processing industry and science and technology, some difficult-to-machine materials are widely used, and cutting processing is developing in the direction of high speed, high precision, and low surface roughness, which puts forward higher and stricter requirements for tool materials. General-purpose high-speed steel can no longer meet the development needs of the situation. In order to adapt to the trend of production development, some manufacturers use high-performance high-speed steel W6M05Cr4V2Al (501 for short) to manufacture reamers, which solves the problem of reaming difficult-to-machine materials. The application of medium frequency induction heating machine has also been widely used.

The reamer used by a company to process the inner hole of military pipe fittings has a length of 220mm, the largest diameter is 10mm, and the thinnest part is 4mm. The material to be processed is 30CrNi2WVA, and the hardness is 40-43HRC. The original hardness is 64 -66HRC M2 steel reamer, the surface roughness of the workpiece after processing is difficult to meet the technical requirements, and the tool life is very short, each reamer can process up to 20 pieces, and the 501 steel reamer with a hardness of 67 - 69HRC, each reamer can process about 100 workpieces, and the service life is increased by 4-5 times.

Annealing by medium frequency induction heating machine. Due to the mixed crystal phenomenon of 501 steel, the annealing temperature is 920-930℃, and the protection is strengthened to prevent oxidation and decarburization. ≤ 255HBW.

Medium frequency induction heating machine quenching. The forged billet is processed into a semi-finished product and straightened before quenching, the straightness is ≤0.10mm, and the stress is relieved. A suitable double-layer fixture is selected, and the salt bath is preheated three times at 600°C, 850°C, and 1 050°C, and heated at 1 200 - 1 20yC. The heating coefficient is 12 - 15s/mm; cooling in stages at 850°C, 450gC medium temperature furnace, and nitrate furnace, and then bending is measured one by one, thermally straightened, and air-cooled.

Cold treatment. After quenching and straightening, cool to room temperature and then perform cold treatment at -78 - -80°C x lh.

Medium frequency induction heating machine for tempering. Straighten after tempering at 560℃x lh, and then repeat tempering, sandblasting, and cold calibration for 3 times. Carry out above-mentioned process by intermediate frequency induction heating machine, hardness 67-69HRC has no problem.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl