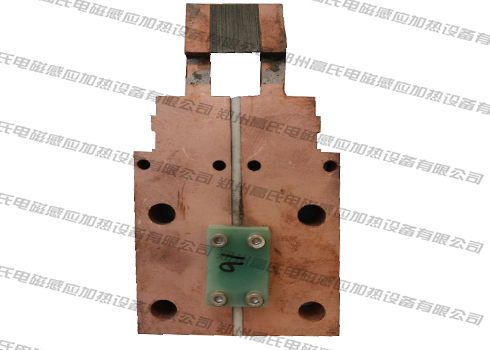

When we mention steel pillow, we first think of railways. The steel pillow has to bear huge friction during the working process. Therefore, the steel pillow is required to have high hardness, wear resistance and service life. For this reason, many manufacturers use medium frequency induction heating machines to quench the steel pillow, and the effect is very good. .

For steel pillows, the medium frequency induction heating machine has a very fast heating speed when it is quenched and heat-treated. Such a fast heating speed effectively avoids the oxidation and decarburization of the steel pillows during the quenching process, and ensures the quenching effect of the steel pillows. After quenching, there is a thicker tough area under the hard layer on the surface of the steel pillow , which has better compressive internal stress, so that the fatigue resistance and breaking capacity of the steel pillows are higher. Even better, the medium frequency induction heating machine can not only perform quenching heat treatment on steel pillows, but also quenching heat treatment on gears, sprockets, shafts, bearings and other auto parts, and its application range is extremely wide.

After the steel pillow is induction quenched by the medium frequency induction heating machine, its hardness reaches 60-65HRB, and the service life is greatly improved, which is 2-3 times that of non-quenching, which meets the work requirements.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl