For some workpieces whose heating time needs to be controlled, conventional medium frequency induction heating equipment does not have this function, and the product requires intermittent heating. Our company can connect a time relay externally according to customer requirements, and connect it to the switch to control the heating of the machine. Time, so as to meet customer requirements, Zhengzhou Gao's external time relay is cheap and easy to use.

The main function of the medium frequency induction heating equipment is heating. Choose the appropriate model according to the customer's workpiece. Another great advantage of the induction heating equipment is that it can cooperate well with many equipment. The application fields of medium-frequency induction heating equipment that can be connected to an external time relay are as follows:

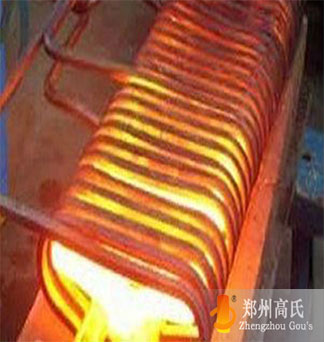

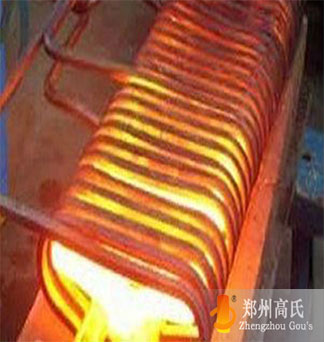

It is used for quenching, welding, annealing, tempering, forging and smelting of various metals; especially local heating and metal heating in different industries.

1. Hot forging and pressing industry --- Whole piece forging, partial forging, fastener forging, drill bit pressing, hot pier for various standard parts and non-standard parts, heating before forging for hardware tools such as pliers and wrenches, etc. .

2. Welding (tin welding, silver welding, brazing) brazing of various metal products, welding of various blades, welding of steel pipes, welding of diamond tools, welding of various shearer picks, various drill bits , The welding of the drill bit.

3. Heat treatment---quenching, annealing and tempering of various metals; especially local treatment, heat treatment of various hardware tools and hand tools, quenching heat treatment of various auto parts, gears, sprockets, hydraulic parts, and machine tool guide rails.

4. Smelting---casting smelting, steelmaking plant smelting, precious metal smelting, laboratory small-scale smelting.

5. Other applications---powder coating, metal implanted in plastic, heating and degreasing.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl