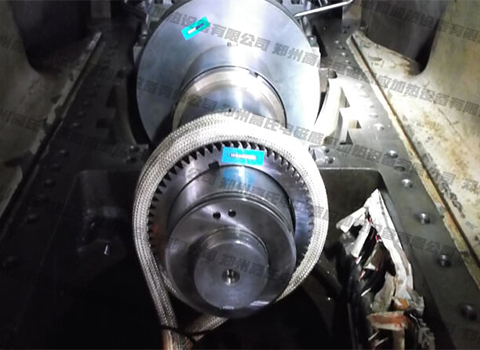

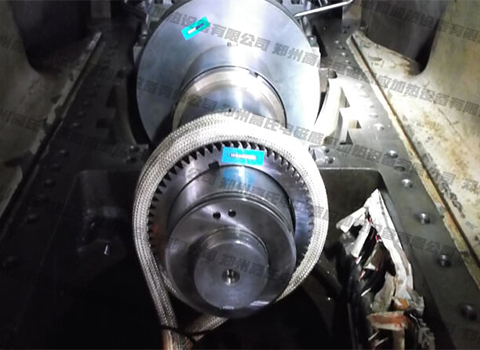

Our induction heating equipment is commonly used for shrink fitting gears and rings in the automotive industry, for shrink fitting tasks on offshore platforms and increasingly for removing giant nuts and bolts in power station turbines.

What are induction heat shrink fittings?

According to the physical properties of metals, metals generally expand when heated and contract when cooled. This dimensional response to temperature change is called thermal expansion. Induction shrink fit is where we use this effect to install or remove parts. The metal part is heated to between 150 °C and 300 °C, which causes it to expand and allow another part to be inserted or removed. For example, when fitting two parts of a tube together, one part is heated until its diameter expands enough to fit over the other part. When the adjacent parts return to ambient temperature, the joint becomes tense and firm - a "shrink fit". Likewise, thermal expansion can be used to loosen joints prior to disassembly.

What are the advantages of using induction heat shrink fittings?

Process control, consistency, accuracy and speed are the key advantages of induction shrink fitting. Induction heating transfer is very accurate. Since heat is generated inside the component, you can only heat the part you want to heat, not the surrounding atmosphere. In addition to reducing the risk of ovality, this is also energy efficient. Additionally, because induction produces extremely uniform heat, ramp up times and soak temperatures can often be precisely controlled using less heat, resulting in accurate temperature control. Unlike traditional heating methods, induction does not involve an open flame, which allows induction heat shrink fittings to be used in a variety of applications in volatile environments, especially petrochemical applications.

Where is the general induction heat shrinkable joint used?

Many industries can benefit from induction shrink fitting. Our induction heating equipment systems are used in the automotive industry for shrink fitting of gears, bearings and rings, in the mechanical industry and for the maintenance of aircraft and trains, in mobile induction heating systems for shrink fitting tasks on ships and offshore platforms and are increasingly Used extensively for installing and removing giant nuts and bolts in power station turbines and bearings and shafts in wind turbines.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl