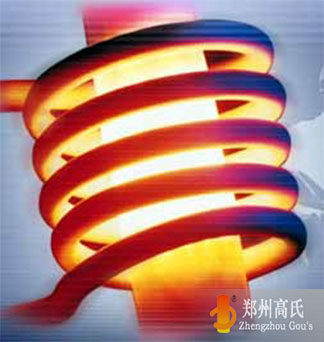

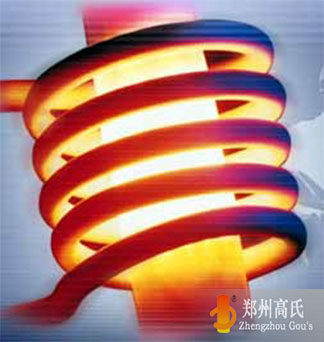

Fasteners are a type of mechanical parts used for fastening connections, and are widely used in machinery, chemical, mold, hydraulic and other industries. As a basic part, its forming also needs to go through a series of complicated processes, such as diathermy, forging and so on. The most widely used equipment for fastener diathermy is medium-frequency induction heating equipment, and the diathermy effect is very good.

Some people are curious, is it complicated to use medium frequency induction heating equipment to perform diathermy heat treatment on fasteners? In fact, the operation process is very simple, that is, put the fasteners into the sensor, and then start the equipment to heat up to 1150°C, which is a good preparation for the next step of forging.

The medium frequency induction heating equipment is produced with advanced IGBT modules, which can replace backward heating methods such as acetylene, coal oven, and box-type electric furnace for diathermy heat treatment on fasteners, and the heating speed is very fast, avoiding the need for fastening of fasteners. Oxidation and decarburization occur during the heat penetration process, which ensures the heat penetration effect of the fastener and makes the temperature of each part of the fastener very uniform after heat penetration. Even better, the medium frequency induction heating equipment performs diathermy heat treatment on fasteners. The heating method is very flexible. Different requirements, traditional equipment cannot do this.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl