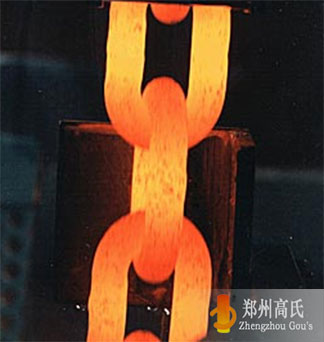

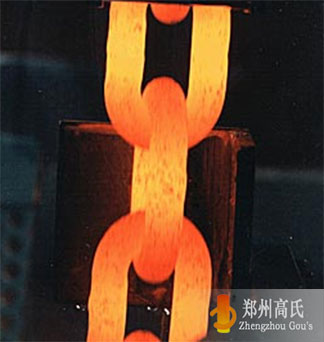

Chains are generally metal links or rings, which are mostly used for mechanical transmission and traction. Its molding needs to go through a series of complicated processes, such as raw material inspection-cutting-heating-shot blasting-welding deburring-heat treatment-stretch correction-inspection pairing-dipping paint storage, etc. In this series of processes, heating is the most important and is the basis for other processes to be carried out. For chain heating, more and more manufacturers have abandoned traditional equipment and switched to medium frequency induction heating equipment.

The medium frequency induction heating equipment is used to heat and heat-treat the chain, which can be used in conjunction with a thermometer, a feeding device, etc., which can not only ensure the accuracy of the heating temperature, but also improve production efficiency. Even better, when the equipment heats the chain, the speed is very fast, and the required temperature can be reached in a short time, which effectively avoids the oxidation and decarburization defects of the chain during the heating process, and ensures the heating effect of the chain.

The medium frequency induction heating equipment is produced by advanced IGBT modules, which can replace the outdated heating methods such as acetylene, coal oven, and box-type electric furnace to heat and heat-treat the chain. The most important thing is that after being heated by this equipment, the chain has no cracks and deformation defects, which lays a good foundation for the next forging work.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl