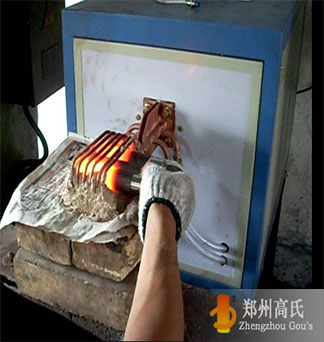

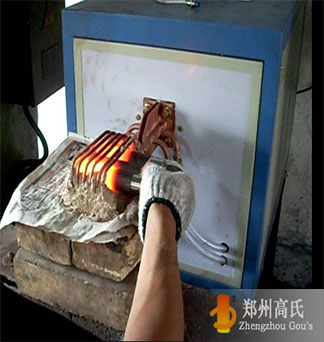

The ball pin is a key component to ensure the stability of the car's handling, the ride comfort, comfort, safety, and the correct and accurate driving of the car. It is also called a ball hinge and a ball joint. Seeing this, we first think that the ball pin needs to be quenched and heat treated, but few people know that the ball pin needs to be heated and heat treated before quenching. Ball pin heating can be carried out with medium frequency induction heating equipment.

The ball pin induction heating, it is preparing for the next process of the ball pin. Different ball pin use different equipment. As for what kind of equipment to use and how much equipment to use, it depends on the specifications of the ball pin, heating speed, heating temperature and other specific conditions.。

The medium frequency induction heating equipment has a complete protection system such as overvoltage, overcurrent, undervoltage, water shortage, phase loss, voltage limiting and current limiting, so as to ensure the reliability and stability of the equipment. When heating, the heating speed is fast. Generally, the heating time does not exceed 10 seconds per piece, which solves the problem that the oxide layer is too thick due to the long heating time of the traditional heat treatment process. Even better, the heating position of the intermediate frequency heating equipment can be freely controlled, and will not generate too much heat to the position that does not need to be heated, which meets the heat treatment requirements of special work, such as local heating of the workpiece.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl