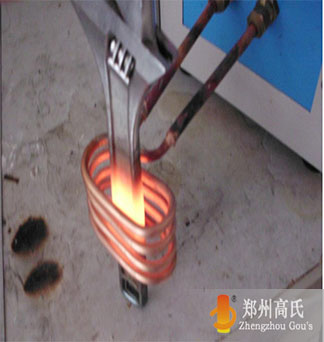

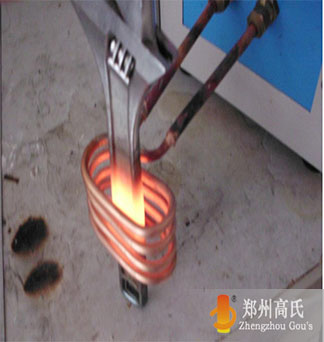

The spanner is a commonly used hardware tool, which is generally used to install and remove tools. During the installation and disassembly process, the spanner must bear huge friction force. For this reason, many manufacturers use medium frequency induction heating power supply for quenching heat treatment to improve the hardness and wear resistance of the spanner, and the effect is very good.

After the spanner is quenched by the medium frequency induction heating power supply, there will be a hardened layer on the surface, about 2-3mm. It is precisely because of this layer of hardened layer that the hardness of the wrench is greatly improved. Our common wrenches usually use our company's 200kw medium frequency induction heating power supply to complete the quenching process.

Medium frequency induction heating power supply, which is produced by advanced IGBT modules, has perfect functions and is very easy to operate. When the spanner is quenched and heat treated, the heating speed is very fast, which effectively avoids the phenomenon of oxidation and decarburization of the spanner during the quenching process, ensures the quenching effect of the spanner, and makes the spanner after quenching have thicker toughness under the hard layer on the surface. The area has better compressive internal stress, which makes the spanner have higher fatigue resistance and breaking capacity. Even better, when the medium frequency heating power supply quenches the spanner, it will not generate noise and dust, which greatly improves the working environment for workers.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl