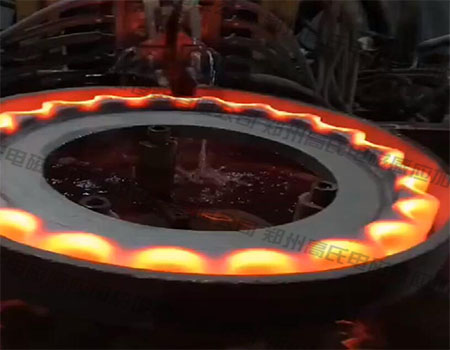

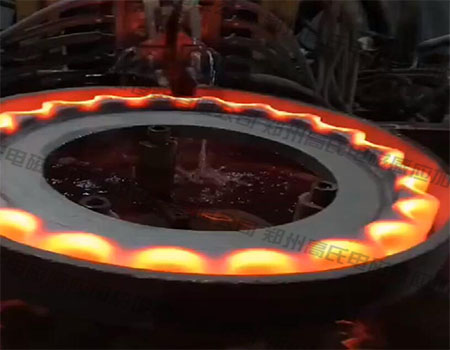

The rope pulley is a pulley that can be hung with a wire rope. During the working process, huge frictional force will be generated between the sheave and the wire rope. Therefore, the sheave is generally required to have high hardness, wear resistance and service life. We usually use medium frequency heating power supply to quench and heat treat the sheave, and the effect is very good.

After the rope wheel is quenched by the medium frequency heating power supply, there will be a hardened layer of 3-5mm on the surface. It is this layer of hardened layer that greatly improves the hardness and wear resistance of the rope wheel, and doubles the service life. many.

The medium frequency heating power supply has a complete overvoltage, overcurrent, undervoltage, water shortage, phase loss, voltage limiting, current limiting and other protection systems, thus ensuring the reliability and stability of the equipment. When it performs quenching heat treatment on the rope wheel, the quenching speed is very fast, which effectively avoids the phenomenon of oxidation and decarburization of the rope wheel during the quenching process, ensures the quenching quality of the rope wheel, and can also be used according to customer requirements. Partial quenching heat treatment, which cannot be done by traditional equipment. Even better, the medium frequency heating power supply can work uninterrupted for 24 hours, greatly improving production efficiency.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl