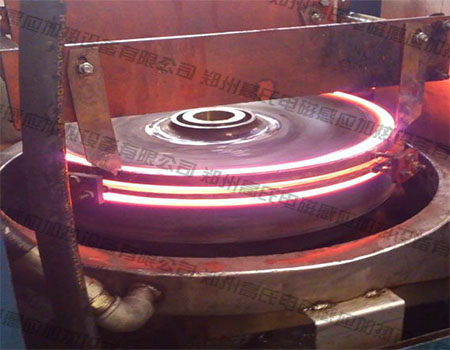

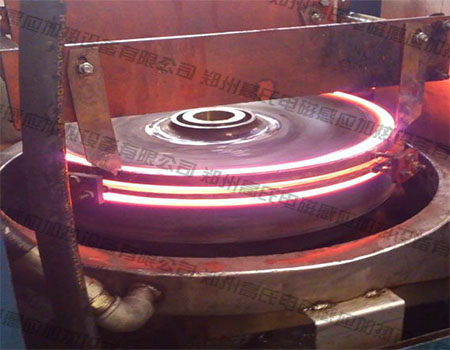

The supporting wheel is one of the four-wheel belts of the crawler-type construction machinery chassis. Its main function is to support the weight of the excavator and bulldozer and let the track move along the wheels. It can be seen from this that the rollers must bear huge friction during the working process. Therefore, the rollers are required to have high hardness, wear resistance and service life. In order to meet the needs of their work, more and more manufacturers now use medium frequency induction heating machines to quench and heat-treat the rollers, and the effect is very good.

The medium frequency heating machine is equipped with alarm indications such as overvoltage, overcurrent, overheating, and water shortage, which makes the equipment have a self-protection function and greatly improves the service life of the equipment. When it performs quenching heat treatment on the track rollers, the quenching speed is very fast, which effectively avoids the phenomenon of oxidation and decarburization of the track rollers during the quenching process, ensures the quenching effect of the track rollers, and makes the surface of the track rollers after quenching There is a thicker tough area under the hard layer, which has better compressive internal stress, so that the fatigue resistance and breaking capacity of the workpiece are higher, which meets its working requirements. What's better is that it can quench and heat treat a certain part of the roller according to the requirements, which is impossible for traditional equipment.

After the rollers are quenched by the medium frequency induction heating machine, there is a hardened layer on the surface, which is about 3-7mm, which makes the hardness of the rollers reach 55-65HRC, and the service life is 2-3 times that of non-quenching, which meets the needs of excavation. machine, bulldozer requirements.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl