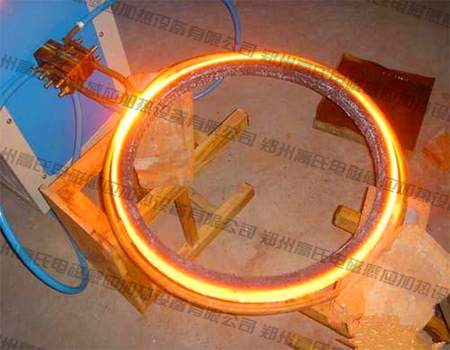

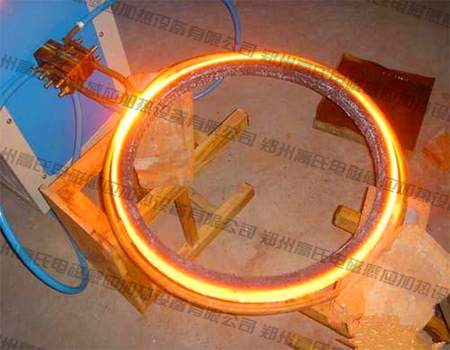

The bearing ring is an important part of the car and plays an important role in the operation of the car. During the working process, the bearing ring has to bear huge friction. In order to meet the needs of production, we usually use a medium frequency heating machine for quenching heat treatment to improve its hardness, wear resistance and service life. The effect is very good.

Bearing ring is an important part of the car, its wear resistance and service life are the key to the operation of the car. After being quenched by the medium frequency heating machine, the surface of the bearing ring has a 3mm hardened layer. It is this layer of hardened layer that greatly increases the hardness and wear resistance of the bearing ring, which meets the working needs. The bearing rings we usually see can be quenched by a 200kw medium frequency heating machine.

The medium frequency induction heating machine has perfect overvoltage, overcurrent, undervoltage, water shortage, phase loss, voltage limiting, current limiting and other protection systems, thus ensuring the reliability and stability of the equipment. When it performs quenching heat treatment on the bearing ring, the heating speed is very fast, which not only avoids the oxidation and decarburization of the bearing ring during the quenching process, ensures the quenching effect of the bearing ring, but also greatly improves the production efficiency of customers. Even better, the medium-frequency induction heating machine will not produce noise and dust when quenching the bearing ring, which greatly improves the working environment of the workers. It meets the national policy requirements and is strongly advocated by the country.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl