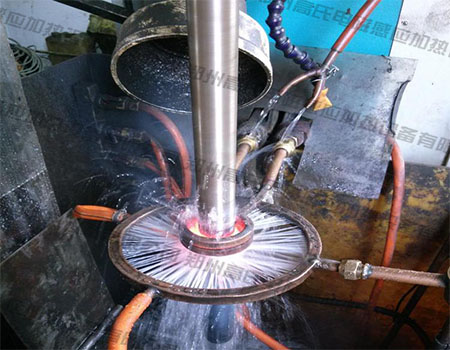

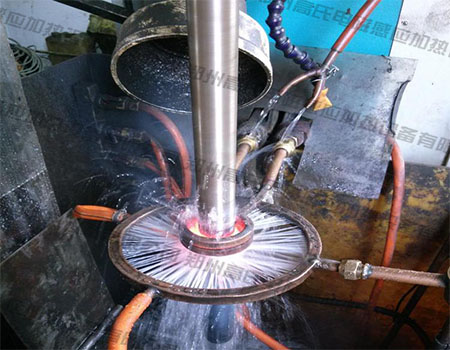

The piston rod is a connecting part that supports the work of the piston. Most of them are used in the cylinder and cylinder motion actuators. It is a moving part with frequent movements and high technical requirements. During the working process, the piston rod needs to bear huge frictional force. Therefore, we often use medium-frequency induction heating machine to quench the piston rod to improve the service life of the piston rod.

After the piston rod is quenched by the medium frequency induction heating machine, there will be a 3-5mm hardened layer on the surface, and the hardness will reach about 60HRC, which meets the working requirements of the piston rod. As for how much equipment should be used for quenching heat treatment, this depends on the diameter of the piston rod.

The medium frequency induction heating machine uses the principle of electromagnetic induction, which can penetrate non-metallic substances and instantly induce heat to any metal in a non-contact form. When it performs quenching heat treatment on the piston rod, the quenching speed is very fast. Such a fast quenching speed effectively avoids Oxidation and decarburization of the piston rod during the quenching process ensure the quenching effect of the piston rod. Even better, the medium frequency induction heating furnace will not produce noise and dust during the working process, which greatly improves the working environment of workers and provides protection for their health.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl