Everyone is familiar with the gun barrel, although it has never been seen in reality, and it has also appeared in TV dramas. Modern artillery barrels are all made of alloy steel. Since the barrels are subjected to very high instantaneous pressure and high temperature during firing, good comprehensive mechanical properties are required in the production and processing of the barrels. Therefore, the material requirements for the gun barrel are very high, and only high-strength alloy steel with trace elements added can meet the requirements. Not only are the production requirements high, but the heat treatment in the later stage also has quite strict technological requirements.

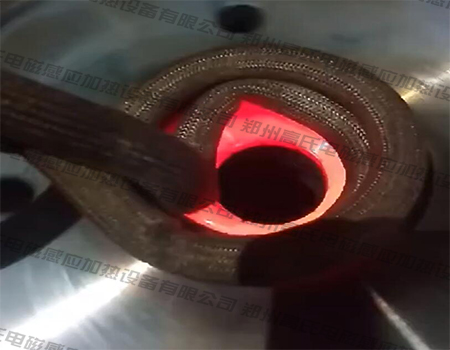

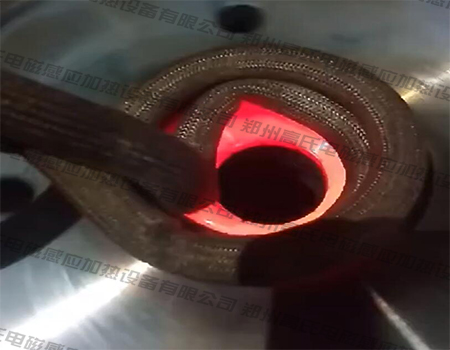

In order to make the barrel can be used normally under high temperature, friction, and pressure, and prolong its life, we choose a 160Kw, frequency 3KHZ medium frequency induction heating machine to quench the inner hole. After quenching, the hardness can reach 36~55.5HRC. After that, tempering is carried out at a temperature of 550°C.

Our medium frequency power supply has low frequency, large current penetration depth and fast heating time. It can be concluded from the test that the medium frequency induction heating machine is used for quenching and heating quickly, easy to control, convenient to operate, can greatly reduce labor intensity, and completely replaces the old-fashioned lead furnace quenching.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl