When it comes to how to increase the hardness, wear resistance and service life of the workpiece, we all know that the workpiece needs to be quenched and heat treated. Now, the more equipment used for quenching is medium frequency induction heating machine. The medium frequency induction heating machine can not only quench the workpiece as a whole, but also partially quench it. Even better, it can quench the plane of the workpiece.

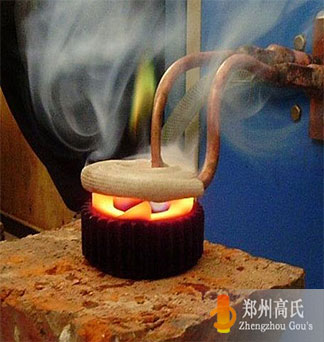

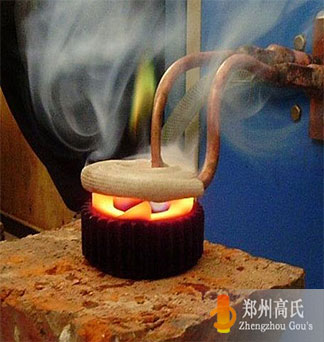

Plane quenching is carried out by traditional equipment, and there are many defects, but induction hardening by medium frequency induction heating machine is different. The picture shows that the medium frequency induction heating machine performs quenching heat treatment on the plane of the gear. Is the effect particularly good? Under normal circumstances, the plane quenching of the workpiece by the medium frequency induction heating machine is generally very fast, usually every few seconds. Such a fast speed avoids the oxidation and decarburization defects of the workpiece during the heat treatment process, and The generation of deformation defects is also avoided. Deformation defects are a concern for everyone. The workpiece quenched by the intermediate frequency induction heating machine has better compressive internal stress, which makes the workpiece have higher fatigue resistance and breaking capacity. Of course, its service life and wear resistance have also been greatly improved.

The medium frequency induction heating machine is produced by the advanced IGBT module in Germany. It will not produce noise and dust to pollute the air during the working process, so you don't have to worry about the people from the Environmental Protection Bureau to check, and it is quite energy-saving. The amount is only 30%-40% of traditional equipment.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl