The outer diameter of the small steel pipe is 20mm, the inner diameter is 7mm, the length is 540mm, each piece weighs about 1KG, and the material is 50 steel, which requires normalizing, quenching and tempering heat treatment.

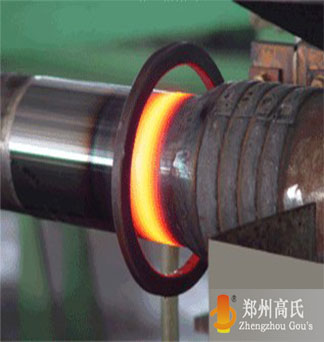

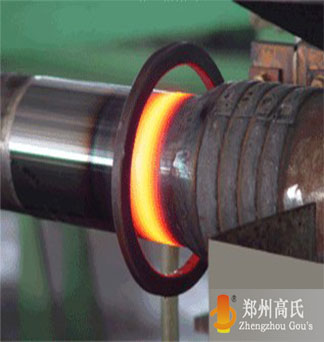

The previous normalizing and quenching of small steel pipes was heated in a 45KW box furnace. Each furnace was equipped with 80 pieces of small steel pipes. The heating time was 1.5h. The normalizing heating temperature was 910-930°C. Power consumption is 0.85KW.h. Now small steel pipes are heat-treated with medium-frequency induction heating power supply. The frequency of medium-frequency power supply is 2500HZ, and the power is 100KW. The medium-frequency inductor used is mainly composed of induction coils, asbestos tubes, heat-resistant bottom plates, and copper splints at both ends. And connect them with copper tie rods. The induction coil is made of 8mmX10mm and 10mmX12nn square pure copper tubes, and the 8mmx10mm rectangular pure copper tubes are arranged at both ends of the induction coil to strengthen the magnetic field strength and compensate for the loss of the magnetic field at both ends. The turns of the 58 turns of the induction coil are insulated with a 1mm thick cloth and adhesive plaster. The heat-resistant bottom plate is made of 1CR18NI9TI material to make an open tube, so as not to heat itself as a circuit. 5 pieces of small steel pipes are heated simultaneously in the inductor, the power is 60KW, the heating temperature is 910-930℃, the production rate is 163 pieces/h, and the power consumption of a single product is 0.37KW.h.

The tempering and heating of small steel pipes was previously carried out in combination with a 35KW lead-bath furnace and a 15KW nitration tank, that is, 18 pieces of small steel pipes were installed on the fixture, one end was cooled by a water tank, and the other end accounted for 95% of the length was immersed in a lead-bath furnace for heating. 6min, take it out for air cooling and then carry out supplementary tempering at the other end in the nitration tank to achieve the purpose of higher hardness at one end of the small steel pipe. The production capacity is 180 pieces/h, and the power consumption of a single product is 0.278KW.h , The small steel pipe is heated and tempered by medium frequency induction, the frequency of the medium frequency power supply is 2500HZ, and the power is 100KW. The medium frequency inductor used is the prototype spiral tube coil, and 6 small steel pipe pieces are placed in the inductor. Installed on the fixture, the section with higher hardness requirements uses a shielding cap to block part of the electromagnetic wave. The heating temperature of this section is lower, and the hardness will be higher. Put the fixture into the inductor and heat it for 56S, the temperature reaches 650-680℃, then take it out. The production capacity is 386 pieces/h, the power is 60KW, and the power consumption of a single product is 0.155KW.h. Because the gas produced by the lead heating and melting of the lead bath furnace is poisonous and harmful to the health of workers, it is very necessary to use medium frequency induction heating to eliminate the lead bath furnace, which not only saves electric energy but also improves the working conditions in the workshop.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl