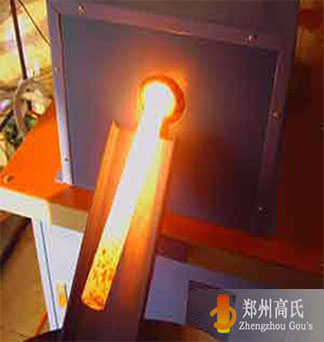

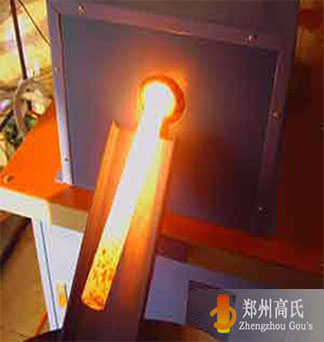

The application of round steel in modern society is quite extensive. The heat penetration of small round steel is not difficult, but how to heat treat large diameter round steel? The medium frequency induction heating machine produced by Zhengzhou Gou's can perform diathermy heat treatment on large-diameter round steel. Customers in Algeria use our medium frequency induction heating machine to conduct diathermy heat treatment on round steel, and the effect is very good.

Performance characteristics of Zhengzhou Gou's medium frequency induction heating machine

1. Fast heating, faster heating speed and even heating (speed can be adjusted and controlled)

2. Easy to install Just connect the power supply, induction coil and water inlet and outlet pipes; small size, light weight, easy to use.

3. The operation is simple and can be learned in a few minutes.

4. Quick start, heating can be started after water and electricity are turned on.

5. Wide heating, can heat all kinds of metal workpieces (replace the detachable induction coil according to the different working switches).

6. The effect is good, the heating is very uniform, the temperature rises quickly, the oxide layer is less, and there is no waste product after annealing.

7. Eliminate high voltage, avoid the step-up transformer that generates nearly 10,000 volts of high voltage, and the safety is very high.

8. Full protection, with alarm indications such as overvoltage, overcurrent, overheating, water shortage, etc., and automatic control and protection.

9. Less power consumption, about 70% less power than old-fashioned high-frequency tube equipment, the smaller the workpiece, the less power consumption.

10. The temperature is controllable, and the heating temperature of the workpiece can be controlled by setting the heating time, so that the heating temperature can be controlled to a technical point.

Applications of Zhengzhou Gou's medium frequency induction heating machine

1. Welding: various woodworking knives, saw blades, sawtooth, mining drills, picks, mechanical turning tools, planers, drills and other alloy tools, welding of diamond tools, and welding of various instruments, meters, clocks and glasses.

2. Heat treatment: quenching, annealing, quenching and tempering of various auto parts and motorcycle parts, high-frequency heat treatment of various hand tools, hardware, gears, and shafts.

3. Smelting: smelting and casting of various precious metals.

4. Forging and molding: rapid heating forging and pressing of various standard parts, fasteners, shafts and bars.

5. Other occasions that require heating: such as thermal assembly of gears and bearings.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl